Torque is a fundamental concept in mechanical and electrical engineering. It plays a key role in motor applications. Understanding how to calculate motor torque is essential to designing efficient and effective motor drive systems. This guide will walk you through the basics of motor torque and show you how to perform the calculations.

1.Understanding Torque

Torque represents the rotational force produced by a motor. It determines how much force a motor can apply to turn an object. The standard unit for measuring torque is Newton-meter (Nm), but it is also commonly expressed in pound-feet (lb-ft) in some regions. Essentially, torque measures how efficiently a motor performs work, especially in applications that require rotational motion.

2.Basics of Motor Torque

Motor torque is affected by a number of factors, including the motor's power output and operating speed. The basic formula for calculating torque (T) in Newton meters is:

T=ω/P

To apply this formula, you need to convert the motor speed from revolutions per minute (RPM) to radians per second using the conversion factor ω=RPM×(2π/60). This step is critical because it adjusts RPM, a common motor speed measurement, to the angular velocity used in the torque formula.

For example, if the motor has an output power of 100 watts and runs at 3000 RPM, first convert the RPM:

ω=3000×(2π/60)=314.16 rad/s

Then calculate the torque:

T=100/314.16=0.318Nm

This calculation provides a theoretical torque value under ideal operating conditions. Realistic factors such as motor efficiency and mechanical losses may require adjustments to these calculations.

3.Step-by-Step Calculation of Torque

Calculating torque for motors involves understanding how to handle different motor specifications and operational conditions. Let's break down the steps:

Determine Motor Power: This is typically given in watts (W). Check the motor specifications for this value.

Obtain Motor Speed: Find the motor speed in RPM from the specifications.

Convert RPM to Radians Per Second: Use the conversion formula:

ω=RPM×(2π/60)

This adjusts the speed into the angular velocity necessary for the torque calculation.

Calculate Torque: Apply the formula:

T=P/ω

Substitute the power and the converted speed into the formula to find the torque.

Example: If a motor has a power of 200 watts and a speed of 1500 RPM:

Convert speed:ω=1500×(2π/60)=157.08rad/s

Calculate torque:T=200/157.08≈1.27Nm

4.Factors Affecting Motor Torque

When calculating torque, consider the following factors to ensure accuracy:

- Motor Efficiency: Not all electrical energy supplied to a motor is converted to mechanical energy due to losses such as heat and friction. Efficiency ratings can be used to adjust the power value in the torque formula.

- Gear reduction: If the motor uses gears, this can change the effective torque output under load. Gears can increase torque but reduce speed proportionally.

- Load Characteristics: The nature of the load (constant, variable, peak load) affects the required torque and motor selection.

5.Real-World Applications and Examples

Understanding how to calculate torque is critical for a variety of applications:

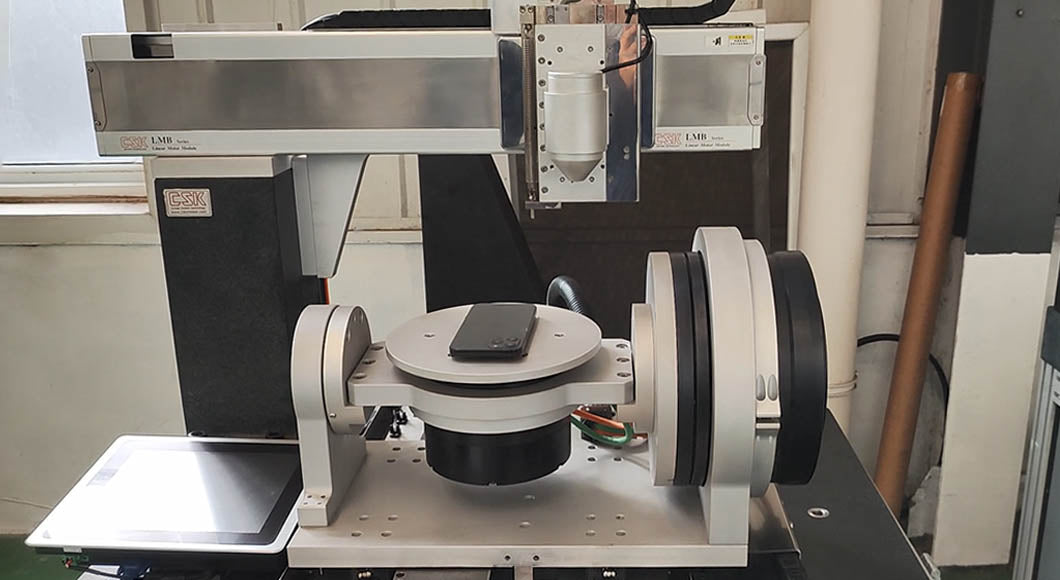

- Robotics: Ensure that the motor has enough torque to handle robotic arm movements without stalling or losing precision.

- Automotive: In electric vehicles, accurately calculated torque ensures optimal performance and battery efficiency.

- Industrial Machinery: Correct torque calculations ensure machinery operates within safe and efficient parameters, preventing mechanical failure.

- Consumer Electronics: In devices such as autonomous vacuum cleaners, accurate torque calculations help design efficient and durable products.

6.Common Mistakes and Misunderstandings

- Ignoring Efficiency: Many people forget to consider motor efficiency. This can lead to an overestimation of the actual available torque.

- Ignoring Environmental Factors: Conditions such as temperature and mechanical resistance can affect motor performance. This can be easily overlooked in calculations.

- Misunderstanding Gear Effects: Gears can significantly change torque output. Not properly considering gear ratios can result in a mismatch between expected and actual performance.

- Confusing Power Ratings: Peak and Continuous Power Ratings can be different. Using the wrong power rating can result in under-calculation of torque.

Conclusion

Mastering how to calculate torque for motors is crucial for optimizing machine performance. This guide has offered a clear path to understand and apply torque calculations effectively. Remember, correct torque calculations enhance the efficiency and reliability of your machines. Always consider motor specifics and operational conditions for accurate results. To delve deeper into this topic or refine your skills, seek additional resources and tools. Your mastery of calculating motor torque can significantly impact the success of your engineering projects.