Product Features

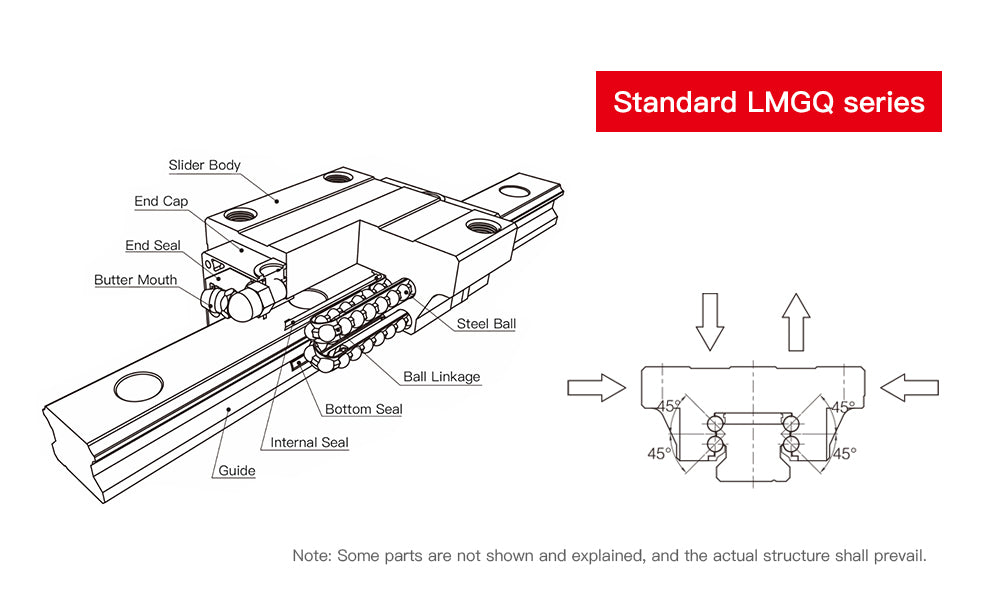

√High rigidity, high load

√Equal load in four directions

√Automatic centering capability

√Fully sealed dustproof system

√High positioning accuracy, good reproducibility

√Low dust generation

√Good smoothness of travel

√High speed and low noise

√Interchangeability

√Common rail design of slider

Specification parameter of linear guideway LMGQ series

Click the download button to get the specification sheet of the Linear guideway LMGQ series.

Applicable Industry

-

Semiconductor Manufacture Device

-

Handling Equipment

-

Packaging Machinery

-

Tool Machine Industry

-

Industrial Robot Industry

-

Injection Molding Machine

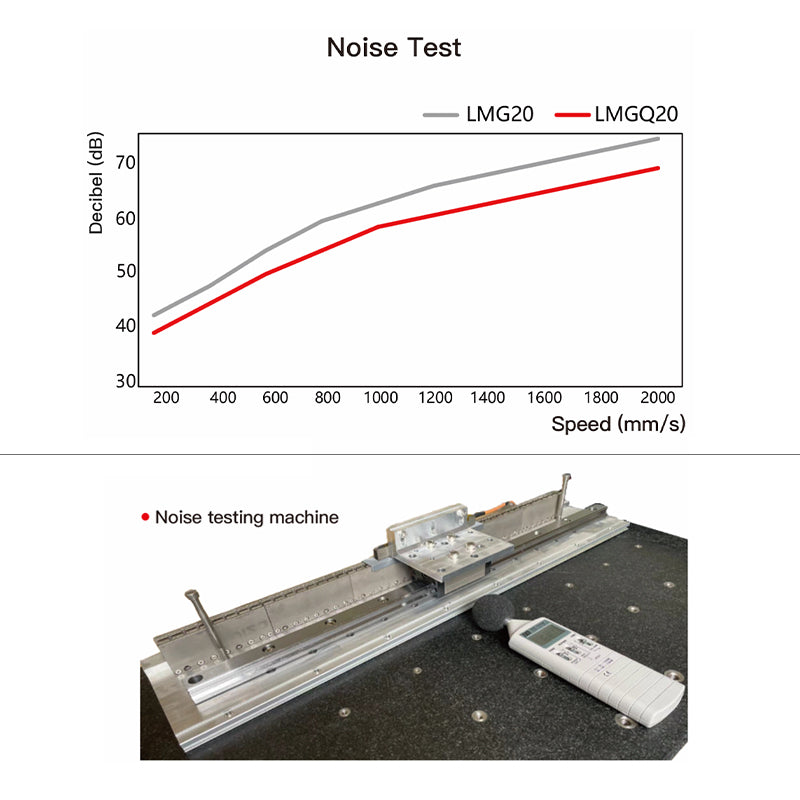

Product Usage Noise Test

LMGQ series use the ball linkage to make the balls evenly and equally spaced up, and eliminate the sharp sound ( high audio sound ) of the balls colliding with each other, through experimental measurement, under different speed conditions, the overall sound of LMGQ series is effectively reduced by 5-7 decibels compared to LMG series.

Test Product:

LMG/GQ20H1SSP0+R1200-30/30N

Test Speed:

200mm/s-2000mm/s

Stroke:

1000mm

Lubrication when using linear guides

Good lubrication is necessary when using linear guides. If there is insufficient lubrication, the friction between the rolling elements and the rolling surfaces will increase during operation, and this may become the main cause of shortened life.

Grease or oil can be selected for the lubrication of the linear guideway, and the lubrication method can be roughly divided into two types: manual lubrication and automatic forced lubrication, which can be properly selected according to the operating speed of the system and the operating environment.

Lubrication method

The greasing frequency of the grease varies according to the conditions of use and the environment. In general, it is recommended to replenish the grease every 100Km. The lubricating grease pre-filled in the slider of CSK linear guide is Lithium soap base No. 2 lubricating grease when it leaves the factory. The lubricating oil lubrication method is recommended to use lubricating oil with a viscosity of 30~150cst. When lubricating oil is used for lubricating, for other installation methods other than horizontal, it may be difficult for the lubricating oil to reach the rolling groove. Please be sure to specify the installation when ordering Way.

Lubrication location

The CSK linear guide series provides the lubricating and oiling positions in the center of the two ends of the slider and the lateral and upper reserved holes of the end cover, as shown in the figure and table below.

In order to prevent the intrusion of foreign matter, the horizontal and upper reserved holes of the end cover are not penetrated. If there is such a horizontal and upper lubrication requirement, please specify when ordering.