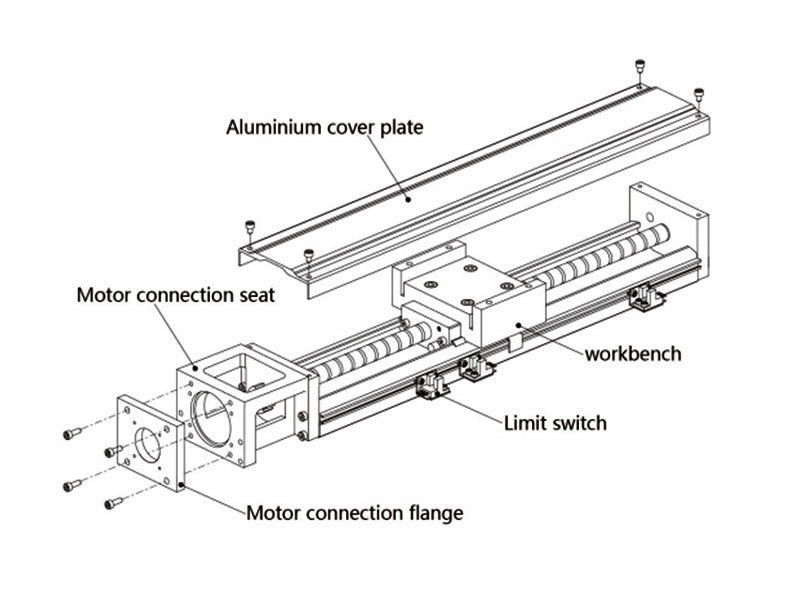

Product Structure

- Easy to design and install, low difficulty in operation.

- High precision, complete the task well.

- Small size and light weight.

- High rigidity and high safety factor

- Optimized design to meet your high requirements.

- Be fully stocked and reduce your downtime.

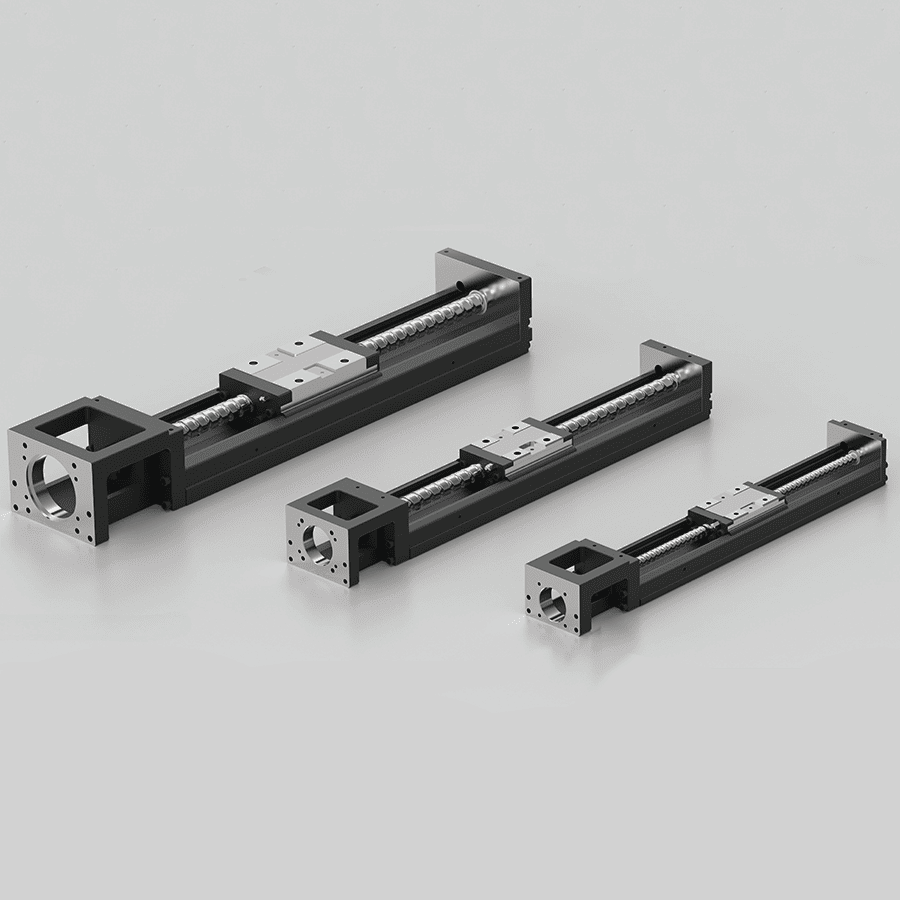

Construction Parameter of Linear Huideway LMK Series

Product Advantages

-

High Precision

LMK linear modules adopt high-precision processing technology to ensure positioning accuracy and repeatability during movement, suitable for high-demand applications.

-

Low Friction

The design uses rolling friction to reduce friction resistance, improve movement efficiency and reduce energy consumption.

-

Strong Load Bearing Capacity

LMK linear modules have a large load-bearing capacity and can withstand heavy loads, suitable for various industrial applications.

-

Self Lubricating

The slider has a built-in self-lubricating module that guides the lubricant to the guide surface for lubrication through engineering fibers.

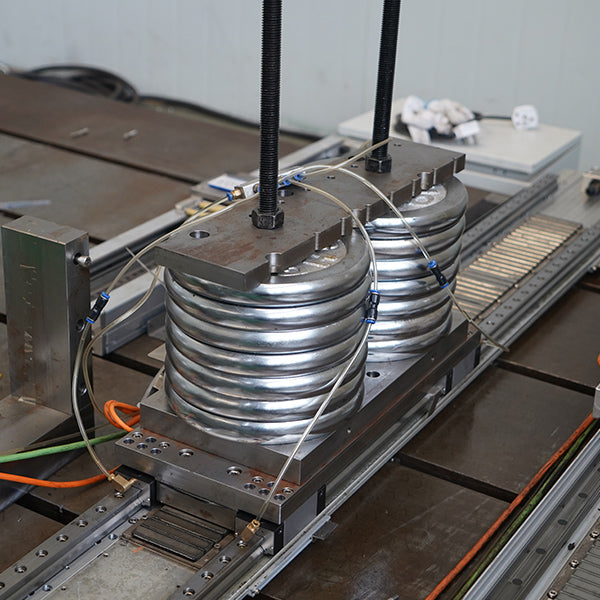

Carrying Capacity Comparison Test

CSK's LMK linear module is designed with a higher load-bearing capacity and is suitable for heavy and high-load applications. Taking a Japanese brand as an example, its load-bearing capacity is more suitable for light or medium load applications.

High Precision Rolling Elements

High-precision rolling bearings and guide rails reduce friction and noise during operation. Shock-absorbing materials are used in the structure of the module to absorb vibration during operation and further reduce noise.

A low-friction lubrication system is used to reduce noise caused by friction and extend the service life of the module.