Product Features

√DFA series ball bearing screws adopt precision machining technology

√Low friction, improved transmission efficiency and reduced energy consumption.

√Able to withstand large axial and radial loads

√Adopt high-strength materials and surface treatment technology

√Provide a variety of diameters and pitches

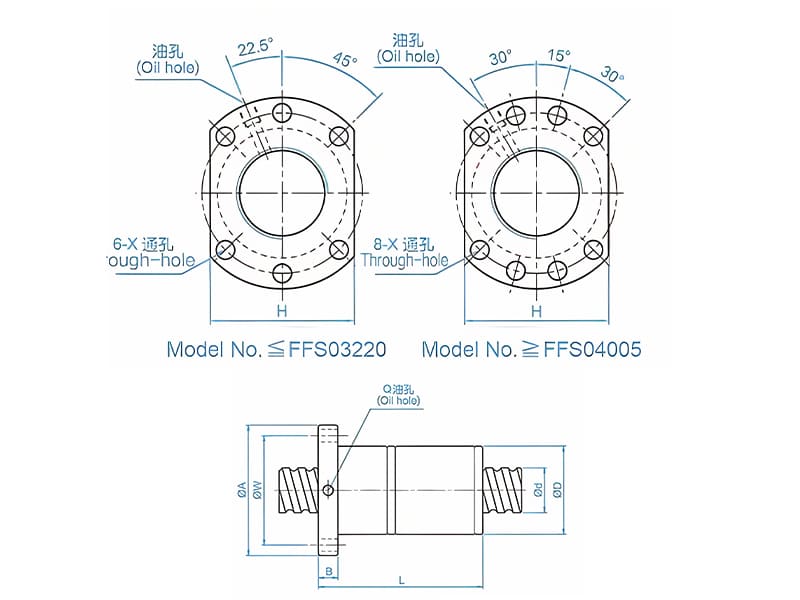

Specification parameter of ball bearing screws DFA series

Click the button below to contact us for the latest quote on ball screws DFA series.

Manufacturing process

-

Grinding

The ball bearing screw DFA series is ground by a high-precision thread grinder. Generally, it can process C5, C3, C1 precision screws. It is suitable for precision CNC equipment, such as CNC milling machines, CNC lathes, machining centers, etc.

-

Milling

The milling process is a one-step process of rolling the thread into a thread shape by extrusion (plastic deformation) between two rollers. It has high processing efficiency, fast delivery and low price. Generally, it can process lead screws with precision of C7 and C10. It is used for equipment with general precision.

Factory processing

Factory machining of ball bearing screws involves several critical steps to ensure their precision, durability, and performance.

Ball screw life

The life of a ball bearing screw is determined by the basic dynamic load rating.

- Relationship between temperature and life

For the temperature of the ball bearing screw, when it is higher than 100 degrees Celsius, the basic rated dynamic load decreases as the temperature decreases. - Relationship between hardness and life

Generally, for the hardness of the screw, when it is lower than HRC58, the basic rated dynamic load should decrease as the hardness decreases.

-

Low friction

-

High efficiency

-

Easy installation