Product Features

√High precision, ensuring tight tolerances and high accuracy in linear motion.

√Low friction

√Capable of handling large axial and radial loads, suitable for heavy-duty applications.

√Available in a variety of specifications to meet different application requirements.

√Made of high-strength materials with surface treatment to enhance wear resistance and extend service life.

√Self-lubricating function to reduce maintenance requirements.

√Smooth and precise linear motion

√Customizable to meet specific application needs

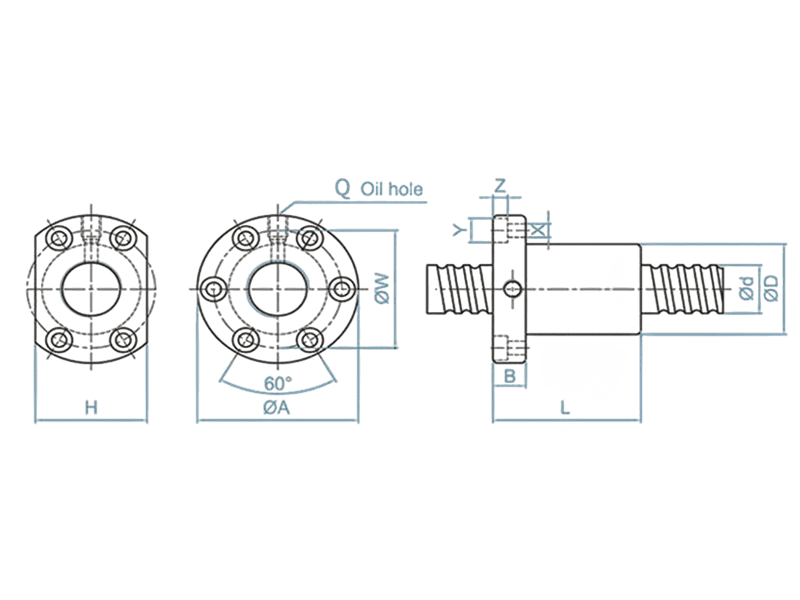

Specification Ball screws FFNI series

Click the button below to contact us for the latest quote on FFNI ball screw series.

Lubrication of Ball Screw

| Lubrication method | Check Interval | Inspection items | Refill or Replacement Interval |

| Automatic intermittent oil supply | Weekly | Oil volume, oil pollution, etc. | Supplement at each inspection |

| Grease | Initial use 2-3 months | Contamination, foreign matter, etc. | Usually replenished once a year |

| Oil bath | Before starting work every day | Oil surface | Replenish during daily inspection |

Cold Rolling VS Grinding

- Cold rolling: A milling process that uses extrusion (plastic deformation) between two rollers to roll the thread into a thread shape in one go. It has high processing efficiency, fast delivery and low price. Generally, it can process screws with c7 and c10 precision. It is used for general precision equipment.

- Grinding: The ball screw is ground by a high-precision thread grinder. Generally, it can process c5, c3, c0 precision screws. It is suitable for precision CNC equipment. Such as CNC milling machines, CNC lathes, machining centers, etc.