Product Features

√High precision

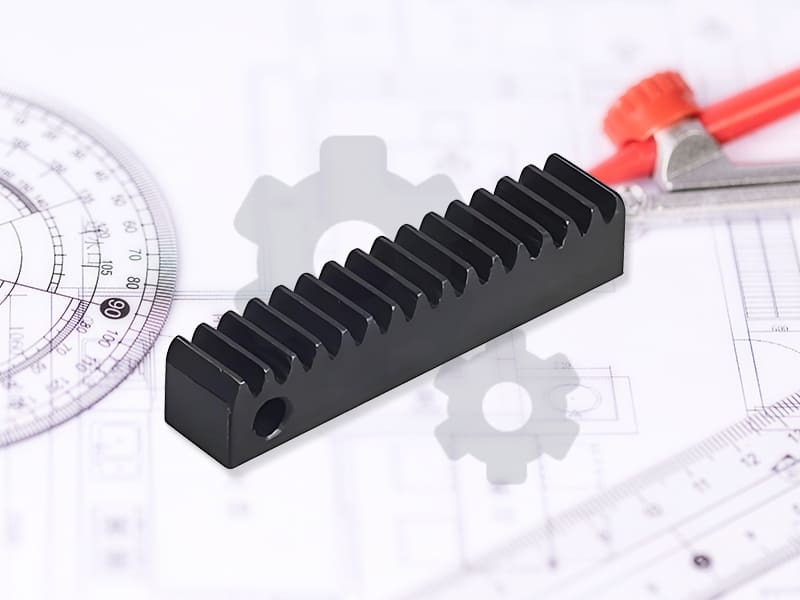

√High-quality materials, made of high-strength steel, tempered

√Good wear resistance, tempering increases the surface hardness of the rack

√Stable heat treatment, can adapt to different working environments

√Easy to install

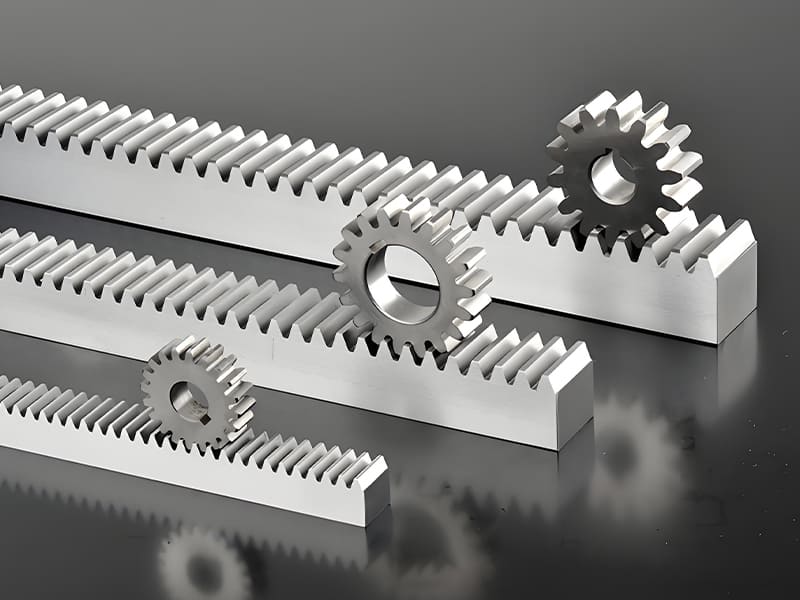

√Strong adaptability, can be used with various types of gears, servo motors and drive systems

√Various specifications available

Specification parameter of linear rack DIN 8

Click the download button to get the specification sheet of the linear rack DIN 8.

Specification

| Specification | Value |

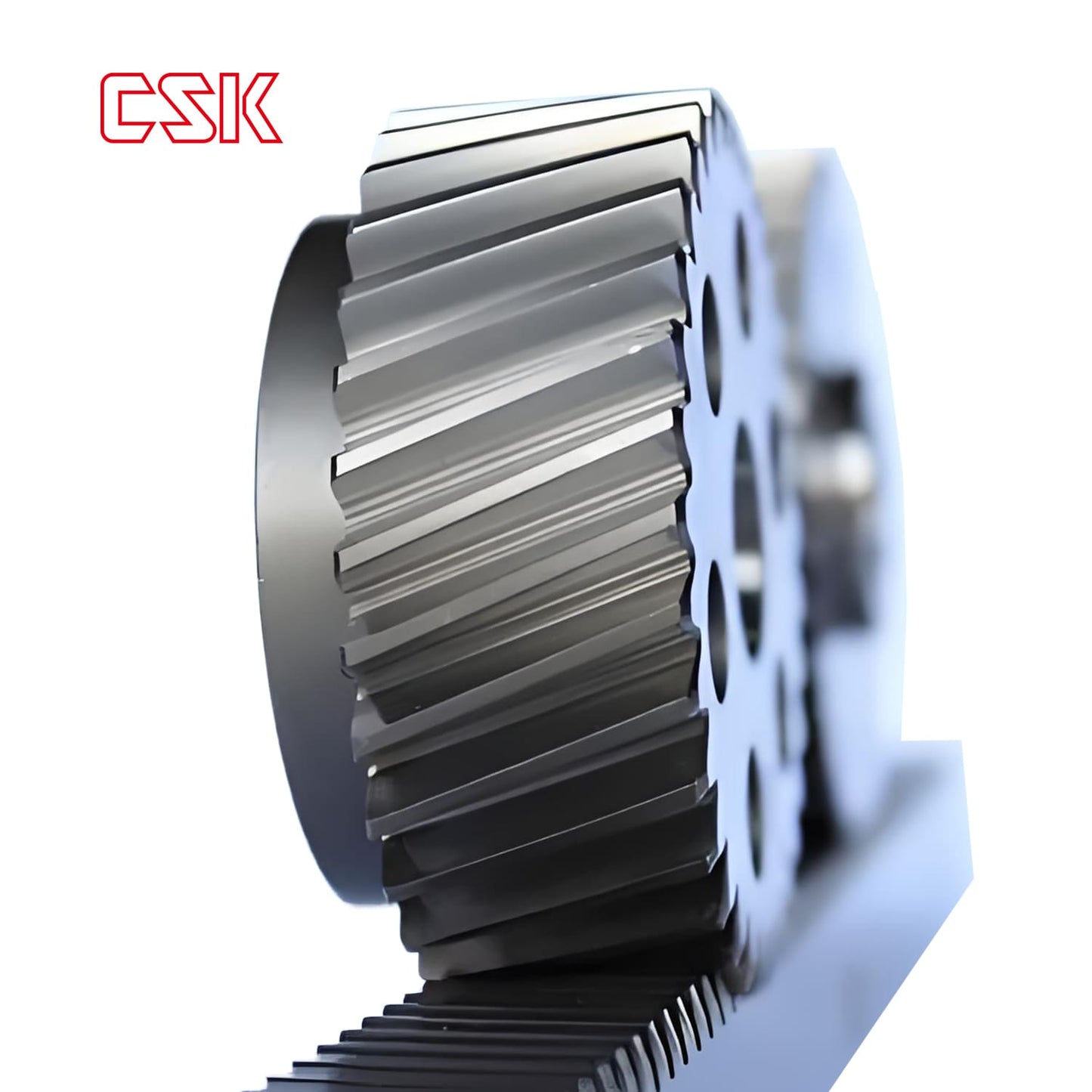

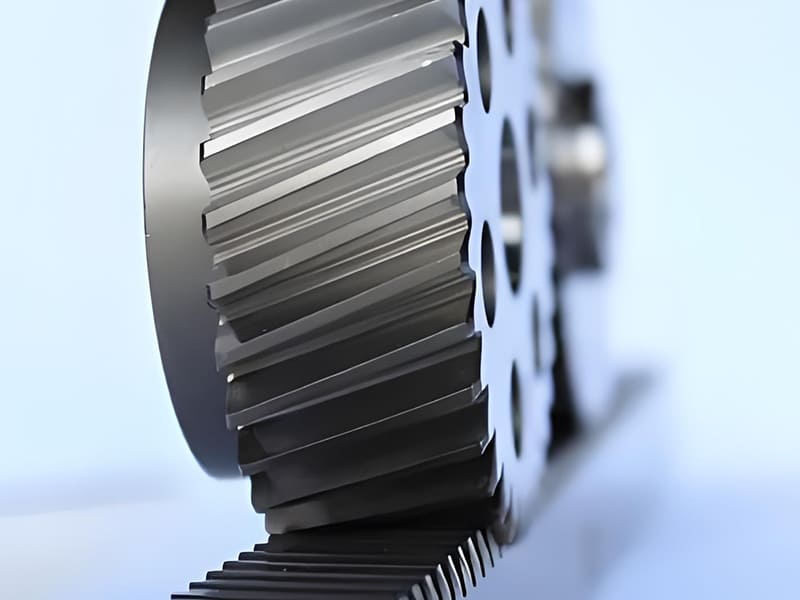

| Type | Spur/Helical Rack |

| Module | 2/3/4/5 |

| Gear Grinding Accuracy | German Standard DIN 8 |

| Material | C45 |

| Hardness | HRC24-27 |

| Heat Treatment | Quenching and Tempering |

Hardness Comparison

DIN8 hardness HRC24-27, DIN 6 hardness HRC50-55, fine milling and tempering racks DIN8 and 6 grade racks have significant differences in hardness and performance.

Product Advantage

-

High Precision

DIN8 grade linear racks have strict manufacturing tolerances to ensure accurate tooth shape and pitch, suitable for high-precision applications.

-

Tempering treatment

After tempering treatment, the hardness and toughness of the linear rack are improved, and the wear resistance and impact resistance are enhanced.

-

High Transmission Efficiency

High-precision linear racks combined with corresponding gears can achieve higher transmission efficiency and reduce energy loss.

-

Surface Treatment

The linear racks are case hardened for increased wear and corrosion resistance.

High Precision Linear Motion

- The motor or other power source drives the gear to rotate through a transmission device (such as a speed reducer).

- As the gear rotates, the gear teeth come into contact with the rack teeth.

- The rotational motion of the gear is transmitted to the rack through the teeth, causing the rack to produce linear motion along its length.

- Equipped with an encoder or sensor to monitor the position of the rack in real time, precise motion control is performed through a feedback control system.