Product features

√Provides excellent positioning accuracy

√Rolling element design reduces friction

√Capable of handling large axial and radial loads

√Designed to operate efficiently at high speeds, increasing productivity in automated processes.

√Using rugged materials and surface treatments

√User-friendly design facilitates quick installation and maintenance

√Available in a variety of sizes and configurations to meet specific application requirements.

√Minimizes vibration and noise during operation

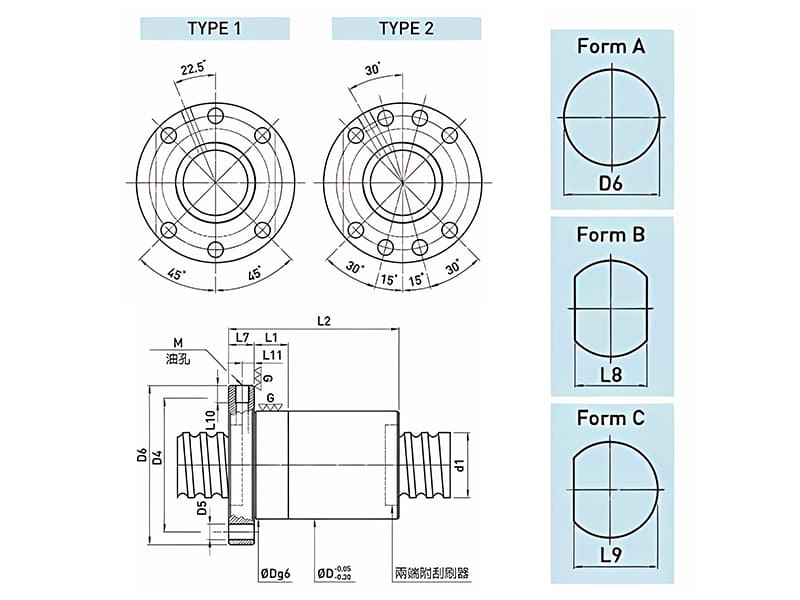

Specification parameter of FSC linear motion screws

Click the button below to contact us for the latest quote on ball screw FSC series.

Support method

In order to improve the axial rigidity, the screw support usually uses a bearing combination with thrust bearing as the main component. Only when the axial load is very small, the radial thrust bearing is used.

-

Double push-free

-

Double push-simple support

-

Single push-single push

-

Double push-double push

-

The characteristic of the FSC linear motion screw is that it converts spiral motion into linear motion or converts linear motion into spiral motion.

Comparison of four support methods:

| Support method | Stiffness | Carrying capacity | Instability |

| Double push-free | Low | Low | have |

| Double push-simple support | Not high | Not high | have |

| Single push-single push | Higher | Higher | None |

| Double push-double push | Highest | Highest | None |

Factory processing

-

The high-precision linear motion screws are strictly quality-controlled from material selection, thread rolling, heat treatment, processing and assembly to ensure the best quality of the product.

-

Check the axial clearance between the nut and the screw to ensure that it meets the design requirements to avoid excessive clearance leading to inaccurate positioning.