Product features

√High precision, FSDC series ball screw rod adopts precision machining technology

√Low friction, using balls as transmission medium, effectively reducing energy loss

√High load capacity, designed to withstand large axial and radial loads

√Strong wear resistance, using high-strength materials and surface treatment technology

√Provide a variety of diameters and pitches

√Easy to install, reasonable design

√Low noise, smooth operation, suitable for environments with strict noise requirements

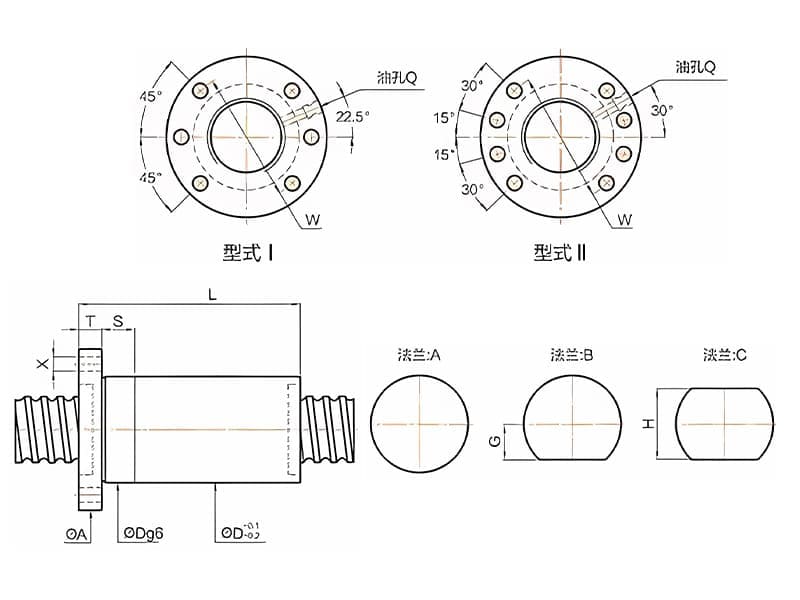

Specification parameter of FSDC ball screw rods

Click the button below to contact us for the latest quote on ball screw rods FSDC series.

Accuracy level

According to GB/T17587.3-1998 (same as ISO 3408-3:1992) standard: the accuracy of ball screw pair is divided into seven levels, 1~7, with level 1 being the highest.

Ball screw rod material

| Material | Grinding Grade | Rolling Grade | Heat Treatment Method |

| Screw | 50CrMo4 | S55C | High frequency quenching HRC58~62° |

| Nut | SCM420H | SCM420H | Carburizing treatment HRC58~62° |

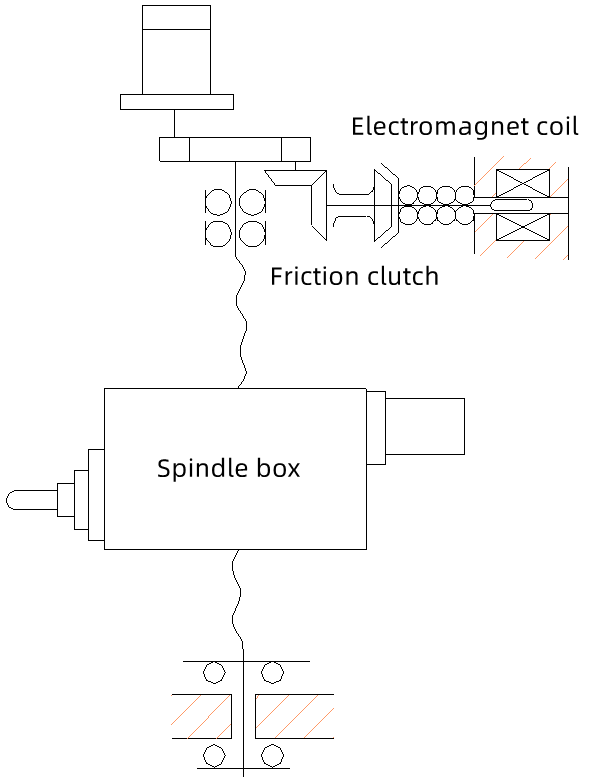

Braking device

Since ball screws do not have a self-locking function, especially when installed vertically, a braking device must be set to prevent the load from sliding down. Common braking devices include

- Electromagnetic brake: The electromagnetic brake applies braking force through electromagnetic force, usually automatically activated when the motor stops, ensuring that the screw remains in the current position.

Quick response, suitable for occasions requiring rapid braking. - One-way overrunning clutch:

The one-way overrunning clutch allows the screw to rotate freely in one direction, and locks in the reverse direction to prevent the screw from reversing.

Effectively prevents the load from sliding down due to gravity, suitable for applications that need to maintain position.