Product Features

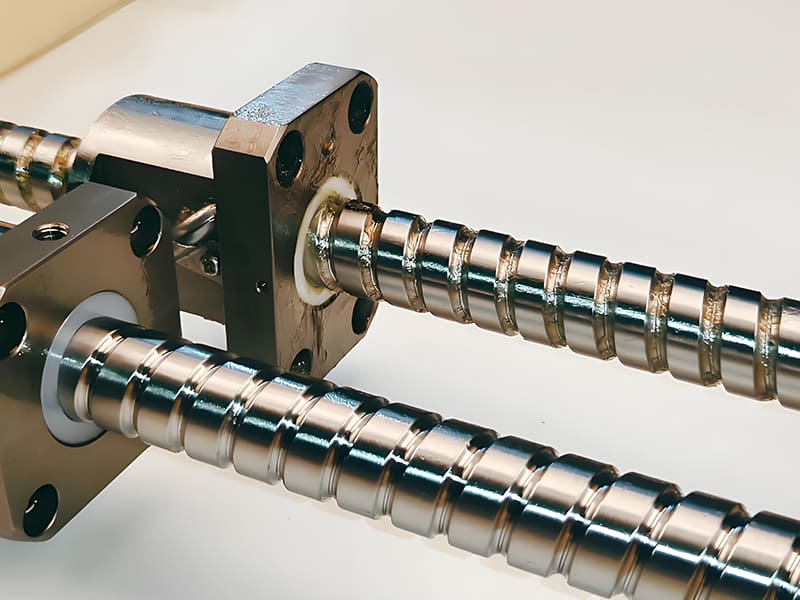

√High precision ball screw, excellent positioning accuracy

√Low friction, ball recirculation system

√Designed to handle high axial loads, suitable for heavy-duty applications

√With a compact design, it can be easily integrated into a variety of machinery and systems, saving space without compromising performance.

√Durability

√Available in a variety of sizes and configurations, which can be customized according to specific application requirements.

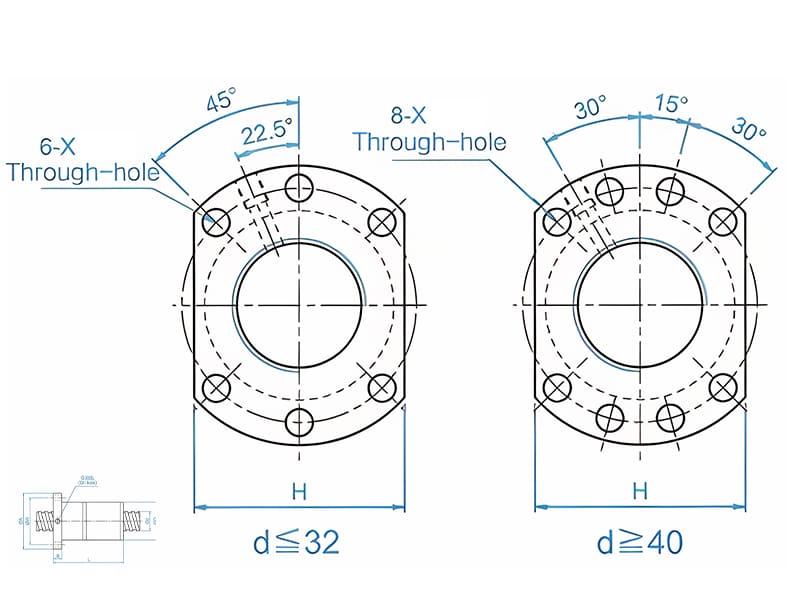

Specification parameter of precision ball screw DFU series

Click the button below to contact us for the latest quote on precision DFU ball screw series.

Maximum manufacturing length of screw

| Diameter | Length |

| d≤20mm | Below 3000mm |

| 25mm≤d≤50mm | Below 6000mm |

| 63mm≤d≤80mm | Below 7000mm |

Recommended length standard:

Aspect ratio Length/diameter:

Best: 1:40

General: 1:60

Ultimate: 1:80

Advantages of DFU Precision Grinding

-

High precision

-

Low friction

-

Strong durability

Lubrication of precision DFU ball screw

- When using a ball screw, it must be lubricated adequately. Insufficient lubrication will increase the wear, cause failures or shorten the lifespan.

- When lubricating the DFU ball screw with grease, use a lithium soap-based grease with a dynamic viscosity of 30~140mm²/s (40°C). When lubricating with oil, use lubricants registered as ISO VG32~100.

- Generally, when thermal displacement of the screw shaft is important in high-speed applications or when used in low-temperature environments, it is recommended to use a lubricant with a lower base oil viscosity. Conversely, when used under conditions such as low speed, high temperature, vibration, and heavy loads, it is recommended to use a lubricant with a higher base oil viscosity.