Product Features

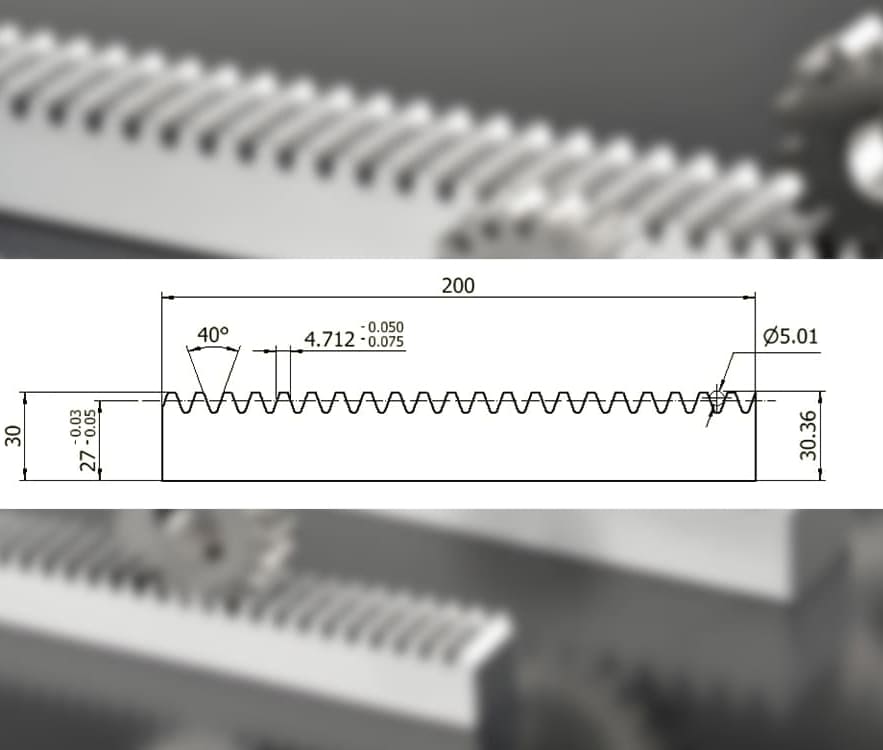

√High precision, racks in accordance with DIN 6A with extremely high dimensional accuracy

√Excellent surface quality

√High strength, made of high-strength steel

√Stability, suitable for high-frequency motion applications.

√Wide applicability

√Low noise, suitable for environments with strict noise requirements.

√Can be customized according to customer needs to meet specific size and tooth shape requirements.

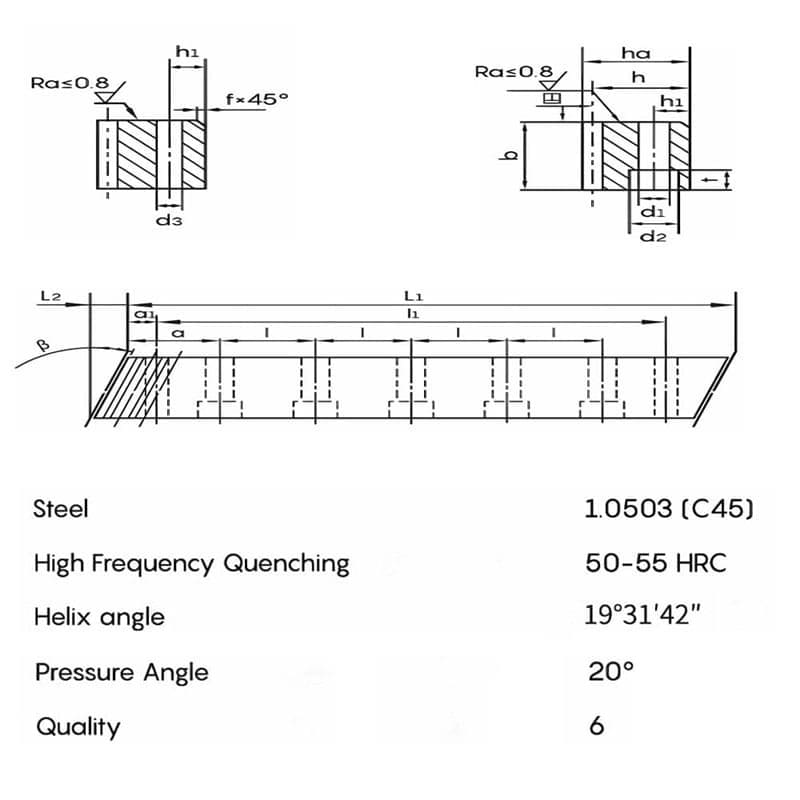

Specification parameter of gear rack

Click the download button below to get the specification sheet of the precisioin ground gear rack DIN 6A.

Application Industry

-

Mechanical Manufacturing

-

Automation Equipment

-

Aerospace

-

Medical Equipment

-

Construction and Civil Engineering

-

Automotive Industry

Gear Rack Pressure Test

Gear rack stress testing is an important method for evaluating the performance of a rack under load. Stress testing can identify potential failures of the rack under high load conditions, ensuring that no accidents will occur in actual applications and ensuring the safety of operators.

Make sure to use appropriate testing equipment, such as a load tester, that can accurately apply and measure loads.

Specification

| Specification | Value |

| Type | Spur/Helical Rack |

| Module | 1.5/2/3/4/5/6/8 |

| Gear Grinding Accuracy | German Standard DIN 6A |

| Material | C45 |

| Hardness | HRC50-55 |

| Heat Treatment | High Frequency Quenching of Teeth |

Accuracy Grade

The gear rack teeth are ground to the German standard DIN6A level, the rack tooth pitch remains consistent, and the allowed deviation is very small to ensure smooth operation during movement. DIN 6A standard racks have high accuracy requirements and are suitable for applications that require high precision and high reliability.