Product Features

- DIN6 grade toothed racks are precision ground, and the tolerances of tooth shape.

- The grinding process makes the rack surface smooth, reduces friction.

- Made of high-strength material, it can withstand heavy loads.

- Precision ground toothed racks have good stability during operation.

- Suitable for various precision mechanical equipment.

- Due to the high precision and good surface treatment of the rack.

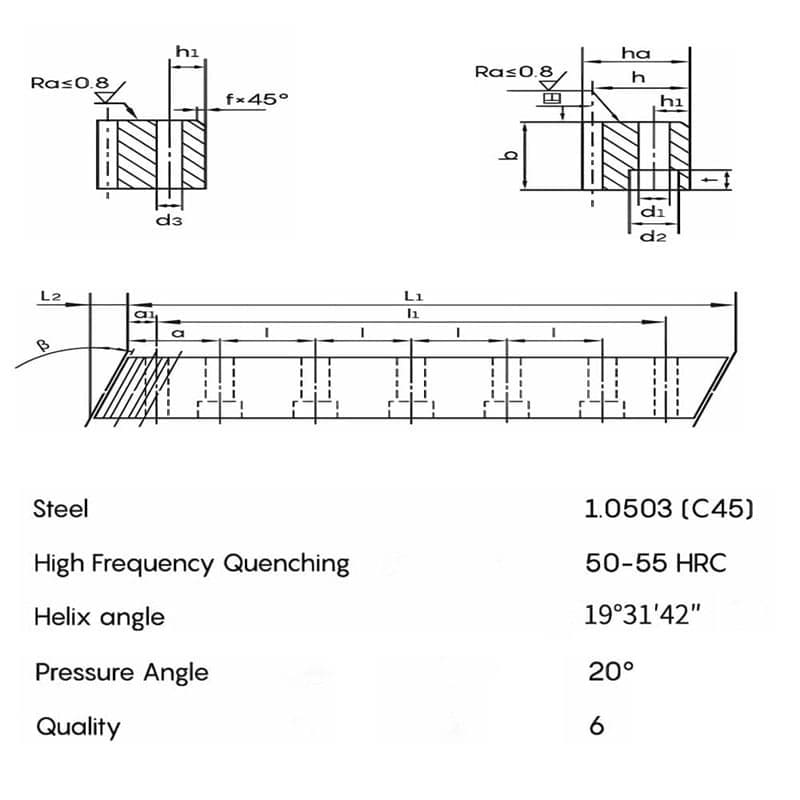

Specification parameter of precision ground toothed rack DIN6

Click the download button below to get the specification sheet of the precision ground toothed rack DIN6.

Specification

| Specification | Value |

| Type | Spur/Helical Rack |

| Module | 1.5/2/3/4/5/6/8 |

| Gear Grinding Accuracy | German Standard DIN 6 |

| Material | C45 |

| Hardness | HRC50-55 |

| Heat Treatment | High Frequency Quenching of Teeth |

Toothed Rack Work

- The working principle of the rack is mainly based on the basic principle of gear transmission. The rack is a linear gear with a series of evenly distributed teeth. The rotating gear that cooperates with the rack is usually circular.

- When the gear rotates, the teeth of the gear mesh with the teeth of the rack.

- The rotational motion of the gear is converted into the linear motion of the rack through the meshing of the teeth.

- The main function of the rack is to convert the rotational motion into linear motion, and it is widely used in mechanical transmission systems.

- The rack can withstand large loads and is suitable for heavy loads and high precision applications.

Product Test Methods

-

Geometric Measurement

Use a caliper, micrometer, or other tool to measure the length, width, and height of the toothed rack to ensure it meets the design specifications.

-

Load Testing

Load test the toothed rack under actual working conditions to evaluate its load-bearing capacity and stability.

-

Hardness Test

Use a Rockwell hardness tester or a Vickers hardness tester to test the hardness of the toothed rack to ensure its wear resistance.

-

Wear Resistance Test

The wear resistance of the rack is evaluated by friction test or wear test.