Product Features

√High precision, RFY series adopts high-precision processing technology

√Balls are used as sliding elements to improve transmission efficiency and reduce energy loss.

√RFY series has an optimized design and can withstand large axial and radial loads, suitable for heavy-duty applications.

√High-strength, wear-resistant materials are used to extend service life and reduce maintenance frequency.

√After special heat treatment, RFY miniature ball screw is suitable for a wide temperature range

√Reasonably designed lubrication system ensures long-term stable operation.

√Widely used in CNC machine tools, automation equipment, medical equipment and many other fields.

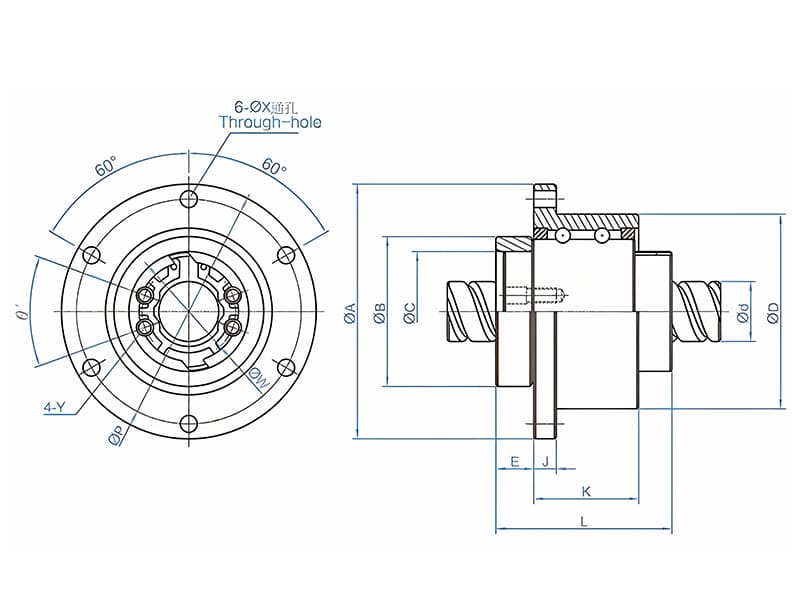

Specification parameter of RFY miniature ball screws

Click the button below to contact us for the latest quote on ball screws RFY series.

Safe use process

-

Lubrication

Lubrication significantly reduces friction, reduces wear and ensures smooth operation.

-

Dustproof

Use protective devices (foldable or telescopic screw covers) to completely protect the screw shaft to prevent dirt and foreign matter (chips and debris) from entering.

-

Using

Prevent reverse rotation; prevent the nut from coming out

-

Installation

When the nut must be removed, use an auxiliary sleeve that is 0.2 to 0.3 mm smaller than the bottom diameter of the screw.

Application Scenario

-

Laboratory equipment

-

Electronics industry

-

Automation equipment

-

Robotics

-

CNC machine tools

-

3D printing

Structure and material

| name | Material | Heat Treatment | Hardness |

| Screw | SCM450(S55C) | Induction hardening | HRC58°~62° |

| Nut | SCM415 | Carburizing and quenching | HRC58°~62° |

| Steel ball | SUJ2 | Roller furnace quenching | HRC60° or above |

Factory processing

-

The factory uses high-precision CNC machine tools and grinders, which can achieve micron-level processing accuracy to ensure the good fit between the miniature ball screw and the nut.

Equipped with advanced processing and testing equipment, it can perform complex processing and improve product performance.